$2 million grant received for developing new ways for recycling plastic

The U.S. Department of Energy (DOE) has awarded a $2 million grant to The University of Akron (UA) as part of a national effort to advance electric vehicle (EV) battery recycling. On Oct. 31, 2024, the Biden-Harris Administration announced nearly $45 million in funding aimed at reducing the costs associated with recycling electric vehicle batteries.

UA’s College of Engineering and Polymer Science (CEPS) will receive $2 million from the DOE, matched by an additional $2 million in cost-sharing support. Dr. James Eagan, assistant professor of polymer science and polymer engineering, serves as the lead principal investigator and is joined by co-principal investigators Dr. Ajay Mahajan, associate dean for research, and Dr. Siamak Farhad, former professor of mechanical engineering. Farhad initially envisioned this project before moving to the University of Tennessee, Knoxville, and is still actively involved in the project.

Recycling Plastics and Polymers

The project, titled “Development, demonstration and integration with the battery recycling plant — an efficient separation and recycling of plastics and composite polymers from EV battery packs,” will involve three local industry partners: Schaeffler, Alterra and a startup company, Black Mass Recycling, to scale the project.

“We have spent almost two years laying the groundwork for this grant by redefining our focus areas, reinvigorating our research center and fostering a dynamic environment for research and innovation,” said Mahajan. “I am proud of our faculty for reimagining a world where we are creating advancements in artificial intelligence, robotics, materials science, clean energy, advanced manufacturing, health care and many other areas.”

Mahajan explained the project’s process. “We take end-of-life EV batteries from manufacturers, separate and recycle the plastics at UA (TRL4), then hand off the materials to a partner company to scale the operation to TRL7, which means producing pellets that battery manufacturers can use to create new battery packs.”

Technology readiness levels (TRLs) are a method for estimating the maturity of technologies during the acquisition phase of a program. TRL is determined during a technology readiness assessment (TRA) that examines program concepts, technology requirements and demonstrated technology capabilities. TRLs are based on a scale from 1 to 9, with 9 being the most mature technology.

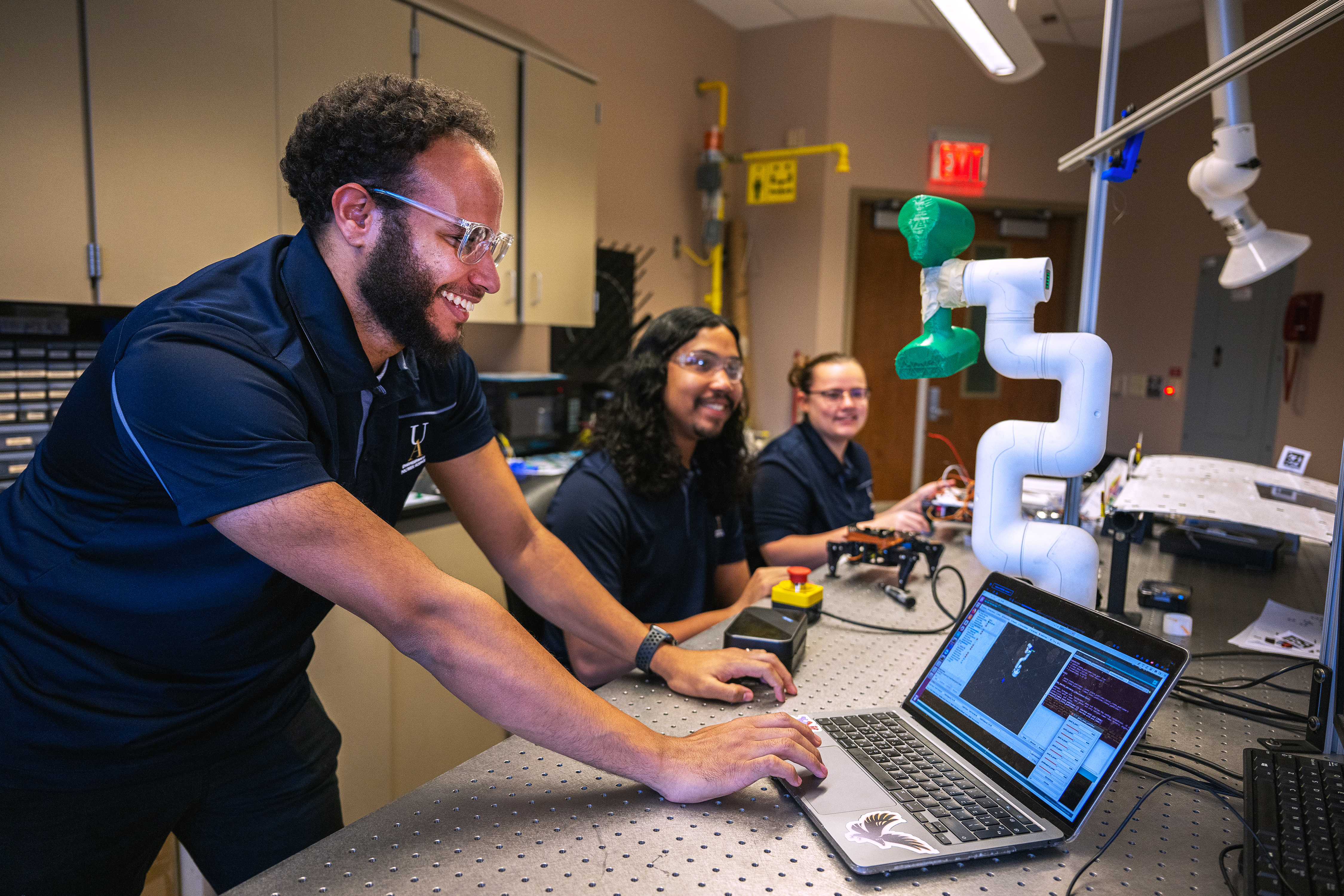

Motaz Hassan, a Ph.D. student working in Dr. Mahajan’s lab, highlighted the role of advanced robotics in this effort. “We are driving advancements in auxiliary plastic recycling through a cutting-edge system featuring a robotic arm, working in tandem with infrared and ultrasonic sensors and guided by a camera performing image processing along a conveyor belt assembly line. This innovative approach demonstrates a proof of concept for efficient plastic separation while paving the way for new recycling processes in electric vehicle batteries."

Influencing Innovation

Beyond EV battery recycling, Hassan also emphasized UA’s broader contributions to innovation. "At the same time, the Autonomous Systems Lab (ASL) is spearheading innovation across biomedical and mechanical fields, developing optimized tympanostomy tubes and kidney stone baskets for minimally invasive medical procedures. Numerous students are working on robotic systems tailored for space servicing operations, validated under zero-gravity conditions. These systems integrate cutting-edge autonomous

navigation, precise localization techniques and adaptive intelligent technologies to ensure reliable and efficient performance in dynamic space environments. With expertise in control systems, microcontroller programming and robotics, ASL collaborates with

government, commercial and academic partners to advance transformative technologies for a wide range of industries."

Reskilling for New Roles

This partnership focuses not only on educating students but also on reskilling and upskilling current employees.

Reskilling refers to equipping workers with new skills for jobs that may be phasing out, while upskilling allows those already in the workforce to acquire additional expertise to advance in their current roles. Both approaches are critical for ensuring that the workforce is well-prepared to meet the challenges posed by emerging industries such as battery recycling and sustainable manufacturing.

In addition to the educational benefits for students, the grant will enable current industry workers to gain new capabilities, ensuring that Ohio’s workforce remains competitive in an increasingly sustainable energy economy.

“This DOE grant will not only help create a new industry but will also offer research and educational opportunities for individuals across all backgrounds and experiences,” added Dr. Craig Menzemer, dean of the College of Engineering and Polymer Science. “It aligns perfectly with our mission to reskill and retool our industrial workforce.”